Your Southern Yellow Pine (SYP) deck is looking better all the time.

By Robert Wyatt, WIR Contributor

What started out as a sketch on a legal pad and some footing holes in your backyard is starting to resemble something to enjoy for years to come.

I want to talk a little about beam span and joist support. Things are about to get real, y’all.

If you can picture it better, think of a deck as just a floor structure. It has joists to support the flooring material (or decking), and posts and beams to hold the unit up off the ground. We’ve already talked about “footings” (the underground pads the piers sit on); “piers” (the foundation for the posts); “ledgers” (the boards attaching the deck to the side of the house and support for the joists); and “posts” (the vertical members that support the beams). “Beams” are the horizontal boards that support the joists; therefore, the length or “span” that the beam can safely hold the weight of the joists is extremely important to the overall integrity of the deck.

The span of a beam is dependent on a few variables. The kind of lumber (since we’re talking SYP, I’ll give you a formula for that), size of lumber, and the load it carries. Beam span maximums are based on a maximum anticipated “live” load (people walking, kids jumping up and down, etc.). The longer the joist, the more area of deck the joist supports, and thus the beam supports. For pressure-treated southern pine no. 2 grade, there is a method that can be used for estimating beam spans. When supporting joists that span 12 feet with no overhang beyond the beam, a double ply beam can span in feet a value equal to its depth in inches. For instance, a double 2×12 beam can span 12 feet; a (2) 2×10 can span 10 feet and so on.

Take a look at the chart below and you get the idea:

X = Joist Length

| X | Species | Post Spacing | ||||||||||

| 4′ | 5′ | 6′ | 7′ | 8′ | 9′ | 10′ | 11′ | 12′ | 13′ | 14′ | ||

| 6′ | SYP | 1-2×6 | 1-2×6 | 1-2×6 | 2-2×6 | 2-2×6 | 2-2×6 | 2-2×8 | 2-2×8 | 2-2×10 | 2-2×10 | 2-2×10 |

| 7′ | SYP | 1-2×6 | 1-2×6 | 1-2×6 | 2-2×6 | 2-2×6 | 2-2×8 | 2-2×8 | 2-2×10 | 2-2×10 | 2-2×10 | 2-2×12 |

| 8′ | SYP | 1-2×6 | 1-2×6 | 2-2×6 | 2-2×6 | 2-2×8 | 2-2×8 | 2-2×8 | 2-2×10 | 2-2×10 | 2-2×12 | 2-2×12 |

| 9′ | SYP | 1-2×6 | 1-2×6 | 2-2×6 | 2-2×6 | 2-2×8 | 2-2×8 | 2-2×10 | 2-2×10 | 2-2×12 | 2-2×12 | 3-2×10 |

| 10′ | SYP | 1-2×6 | 1-2×6 | 2-2×6 | 2-2×6 | 2-2×8 | 2-2×8 | 2-2×10 | 2-2×12 | 2-2×12 | 3-2×10 | 3-2×10 |

| 11′ | SYP | 1-2×6 | 2-2×6 | 2-2×6 | 2-2×8 | 2-2×8 | 2-2×10 | 2-2×10 | 2-2×12 | 2-2×12 | 3-2×10 | 3-2×12 |

| 12′ | SYP | 1-2×6 | 2-2×6 | 2-2×6 | 2-2×8 | 2-2×8 | 2-2×10 | 2-2×10 | 2-2×12 | 3-2×10 | 3-2×10 | 3-2×12 |

| 13′ | SYP | 1-2×6 | 2-2×6 | 2-2×6 | 2-2×8 | 2-2×8 | 2-2×10 | 2-2×10 | 2-2×12 | 3-2×10 | 3-2×12 | 3-2×12 |

| 14′ | SYP | 1-2×6 | 2-2×6 | 2-2×6 | 2-2×8 | 2-2×10 | 2-2×10 | 2-2×12 | 3-2×10 | 3-2×12 | 3-2×12 | 3-2×12 |

| 15′ | SYP | 2-2×6 | 2-2×6 | 2-2×8 | 2-2×8 | 2-2×10 | 2-2×12 | 2-2×12 | 3-2×10 | 3-2×12 | 3-2×12 | Eng Bm |

| 16′ | SYP | 2-2×6 | 2-2×6 | 2-2×8 | 2-2×8 | 2-2×10 | 2-2×12 | 2-2×12 | 3-2×10 | 3-2×12 | 3-2×12 | Eng Bm |

Joist sections cantilevered over beams must be calculated as (2x length) for beam sizing.

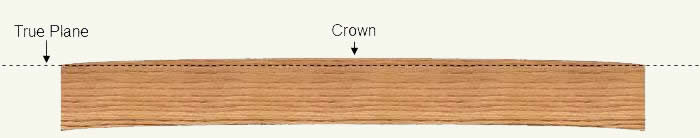

A cantilevered beam (beam that allows you to extend the deck a few feet beyond the edge of the supporting structure) is positioned below the joists to support the weight of the frame. Cantilevered beams are stronger than flush style beams because they rely on the strength properties of the wood rather than the individual mechanical and fastener connections. Notching your posts lends itself well to cantilevered beam construction, and adds to the integrity of the deck. In order to install a cantilevered beam you must have enough clearance below the joists to install the beam. Allow for a minimum of 6” airspace between the ground and the bottom of the beam. Always remember to install the beam crown side up so the weight of the deck will level itself. If you install a beam crown side down the deck is more likely to sag.*

* Side note: In case you’re like I was and had no idea what the “crown” of a piece of wood was…Lumber (of almost any kind) is rarely perfectly straight. The crown of a piece of lumber is the upward arching curvature you see when you look down its narrow edge. To see the crown of a 2 by floor joist, you drop one end of the board on the ground and pick up the other end. Rotate the piece of lumber so that the 1.5 inch wide surface is pointing to the sky. As you orient your eye, so that you are looking down this finished edge towards the ground, you will almost always see some amount of curvature. It is possible to have a piece of lumber that is perfectly straight or one with very little curvature, but they are few and far between. You want the curvature or crowns of the joists to point to the sky after the joists are nailed in place.

Here’s a general idea of how your beams and joists should start coming together in preparation for the decking and handrails.

I really didn’t intend this entry to come off sounding like an episode of the Big Bang Theory, but there’s a lot to remember in preparing for a sturdy frame for your deck and it’s definitely related to math and science. Trust me, it’s all worthwhile. Next time, believe it or not, we’re going to finally lay down some decking boards and give you a place to sit that deck chair and umbrella!