When building a deck, fence, pergola or other outdoor wood structure, you’ve likely come across galvanized steel screws in the recommendations. Using the right type of hardware goes hand-in-hand with the longevity of your exterior wood products and is just as important as choosing the right type of lumber.

Pressure-treated wood is infused with the latest generation of preservatives, such as widely known and trusted copper azole (dissolved – CA-C or micronized – MCA). These treatments can make the wood more corrosive to metal components, which makes choosing the proper fasteners essential for building safe, durable outdoor structures like decks and fences.

We have the breakdown on galvanized steel fasteners and why they should be the go-to for any outdoor project using pressure-treated Southern Yellow Pine.

What Is Galvanized Steel?

Galvanized steel is steel that has been coated with a protective layer of zinc. This zinc coating acts like armor, guarding the steel underneath from rust and corrosion, which is especially important for projects in outdoor environments where moisture is a constant factor.

There are different ways to apply this zinc layer, but hot-dip galvanization is the most common method. It involves dipping steel into molten zinc, which creates a thick, durable coating that holds up well against the elements.

Why Use Galvanized Steel with Pressure-Treated Lumber?

Wood like Southern Yellow Pine is treated with preservatives to resist decay, rot, and termites. While that’s great news for your project’s long-lasting performance, those same chemicals can be harsh on metal fasteners and hardware.

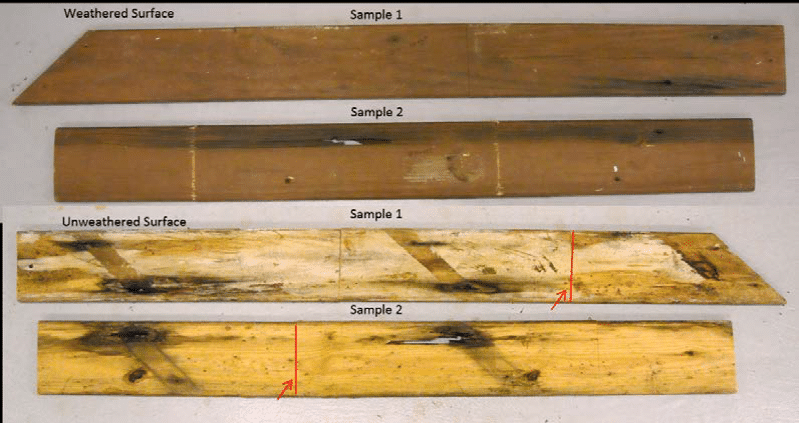

If you use the incorrect fasteners, you can expect iron rot; and, fasteners that are not corrosion-proof can cause wood degradation. As the oxidation of rusting occurs, it creates a low molarity of acid that can cause the wood to dissolve and look charred. Therefore, it is important to use stainless steel and appropriately hot-dipped galvanized fasteners when building outdoor structures.

Since some preservatives can be corrosive to fasteners, it is imperative to use building-code approved, corrosion-resistant hardware suitable for pressure-treated wood. Non-metallic and micronized copper azole (MCA) preservatives are less corrosive to connectors and fasteners and can be used in direct contact with aluminum products, even in applications that could get wet regularly. This is not the case with all preservatives. Check the end tags of treated wood to learn about the preservative used. You can also connect with the preservative company to see what types of fasteners and connectors they recommend. For coastal installations, we recommend code-approved stainless steel.

Viance, who manufactures preservatives for pressure-treated wood, recommends hot-dipped galvanized or stainless steel fasteners and connectors, specifically G185 hot-dipped galvanized connectors for exterior use.

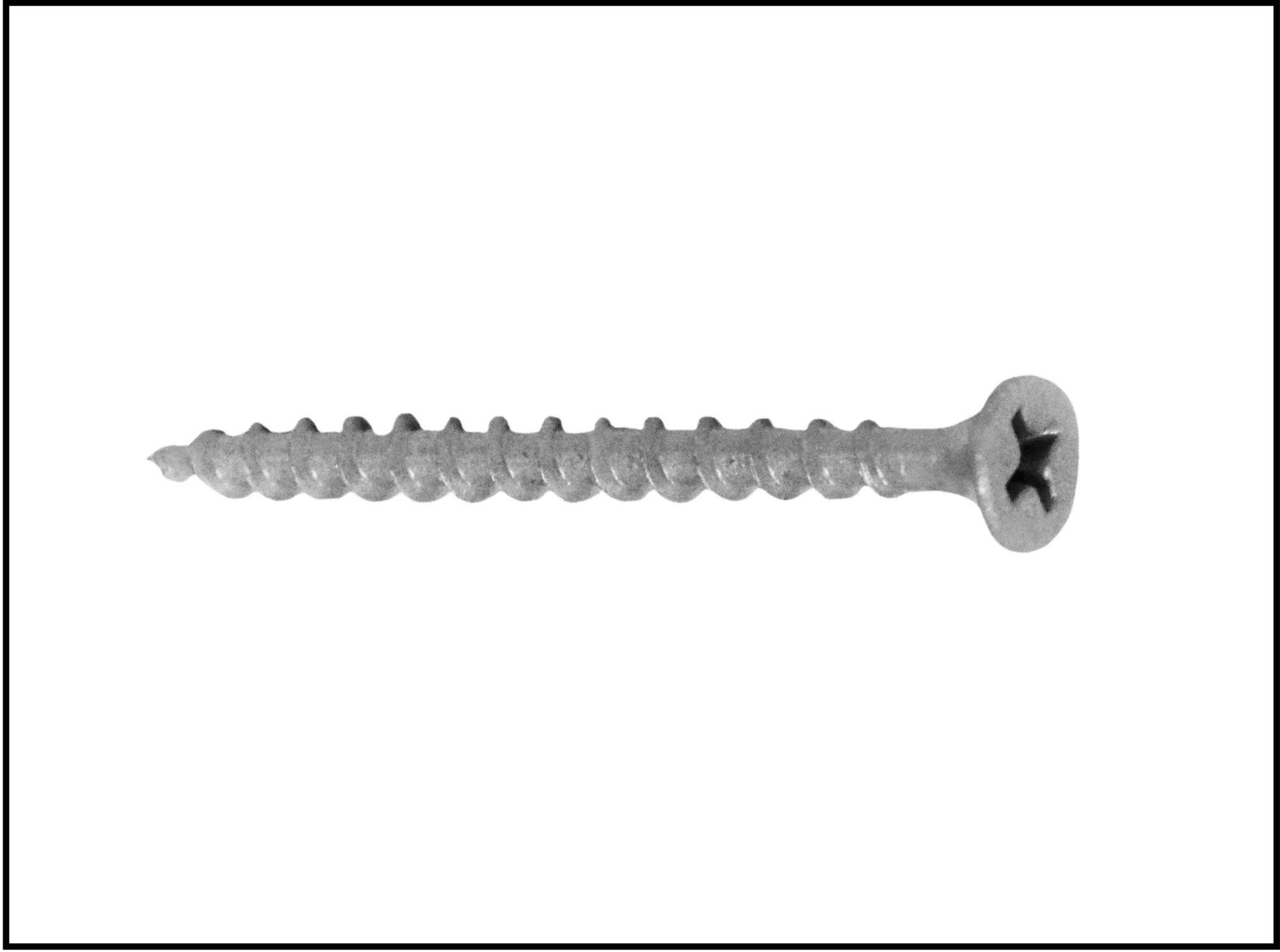

How to Spot Galvanized Fasteners

Hot-dipped galvanized fasteners (meeting ASTM A 153) and connectors (ASTM A 653 Class G185 sheet), or better, are recommended for use with pressure-treated wood. Galvanized screws, nails, bolts, and brackets usually have a dull gray or mottled finish. Some may even be labeled as G185 or hot-dipped, which indicates a thicker zinc coating and better protection.

Additionally, aluminum flashing (3105 or similar alloy) may be used in contact with micronized copper azole (MCA) treated wood in interior or exterior, above ground applications that are damp or intermittently wet. For dissolved copper azole (CA-C) preservative treated wood or whenever treated wood is subject to immersion or frequent or prolonged wetting, factory-coated aluminum or an insulating moisture resistant barrier should be used between the treated wood and the aluminum.

If your project is in a high-moisture area, or if your project is staying outside and meant to last season after season, make sure you’re using corrosion-resistant fasteners.

The bottom line

Galvanized steel screws shine when it comes to long-lasting outdoor projects. The zinc coating acts as protection between the wood’s pressure-treated preservatives and the steel of the screw, preventing corrosion that can weaken joints, create iron rot or compromise connections over time.

Without the right protection, standard steel fasteners can corrode, rust, and even stain the pressure-treated wood. Over time, that could lead to structural issues and expensive repairs. So it’s important to build it right, right down to the fasteners.